3D Printed Tooling Supports Prototype Foam Seating

3D printed tools could be a faster, more affordable way to prototype and produce foam parts for automakers and other OEMs.

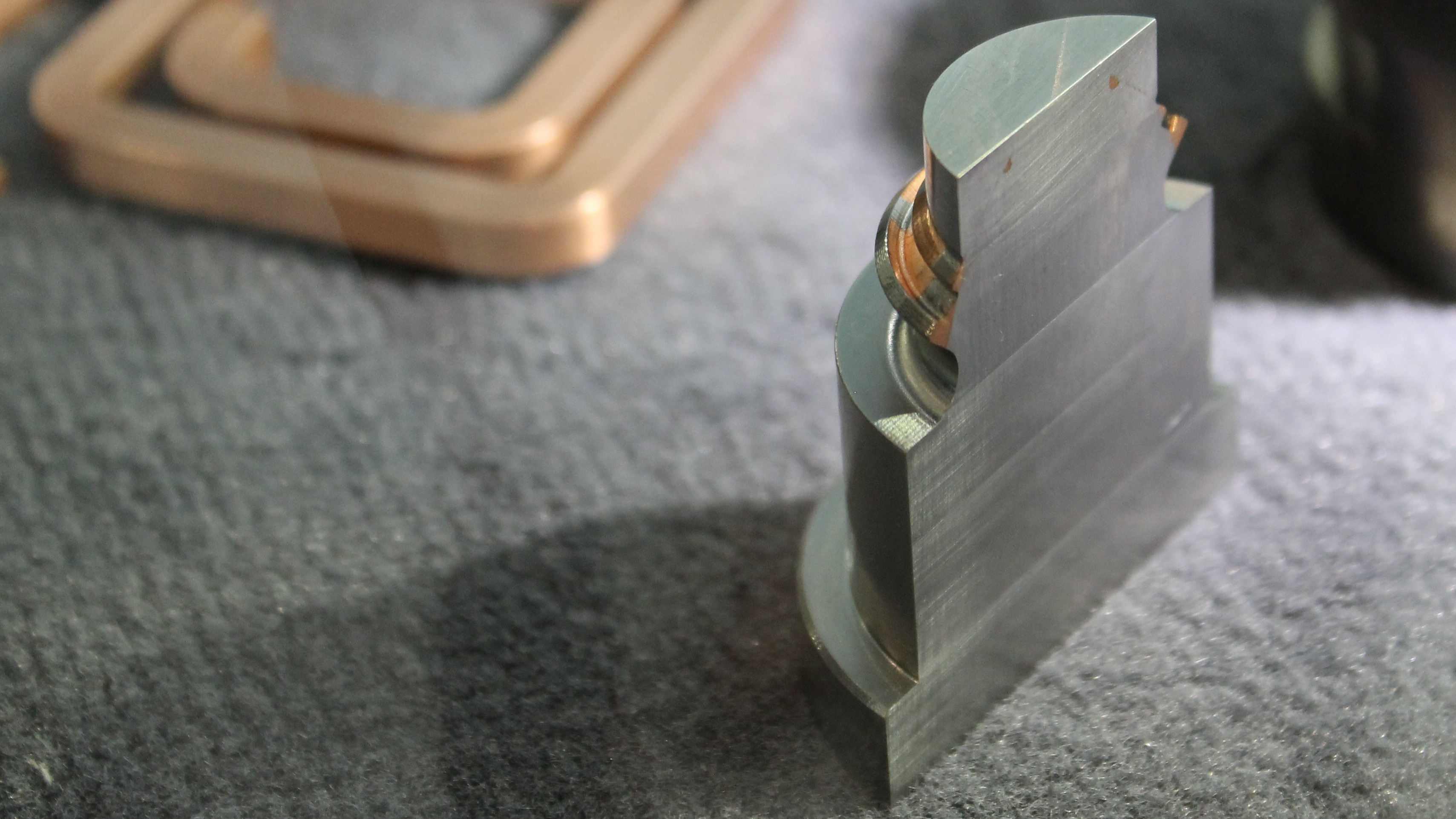

Automotive manufacturers and other OEMs require mold tooling to build foam components like seat cushions. 3D printed tools could be a faster, more affordable way to prototype and produce these parts.

Catalysis Additive Tooling , LLC

Home - Catalysis Additive Tooling

3D Printing at the Turn of Iten's Century

3D Printed Tooling Supports Prototype Foam Seating

3D Printed Kneepad in TPU 85A

3D Printed JetPack Accelerates the Product Design Cycle

Introducing Formlabs' First Flexible SLS 3D Printing Material: TPU 90A

AM's 2020 Advance: How the Crisis Created Conditions for Additive

Hermle Combines Metal Powder Application Process with Five-Axis

Stock Up With Wholesale polyurethane foam prototype Online

3D Printed Tooling Supports Prototype Foam Seating

/wp-content/uploads/2023/07/concept-brea

A growing trend: 3D printing of aerospace tooling