Plastic Injection Mold Base Functions and Structure - Parts of Mold

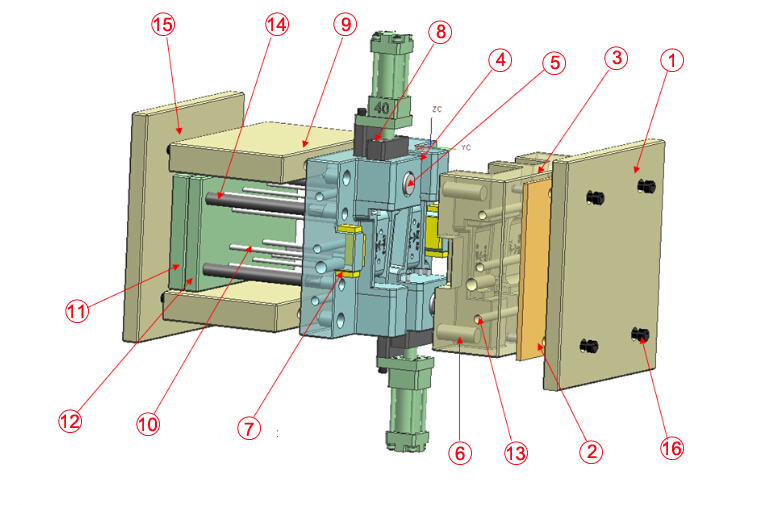

A plastic mold plate is any plate required to build a complete plastic mold, and all injection mold plates used for molds have the main requirements, they are : 1. Good corrosion resistant 2. Good Machinability. 3. Easy to clean 3. Good heat transfer. 4. Homogeneity of steel. 5. Easy ability. 6. Low Cost. at the picture below you can see 3 plate mold base type with closed position, basically, 3 plate type injection mold and 2 plate injection mold have some main plate structure, see explanation about plastic injection mold construction type to understand more, explanation plastic injection mold parts and function below based on the number at those 3 plate mould pictures: 1. Fixed Clamping Plate or Top Plate The fixed clamping plate or the top

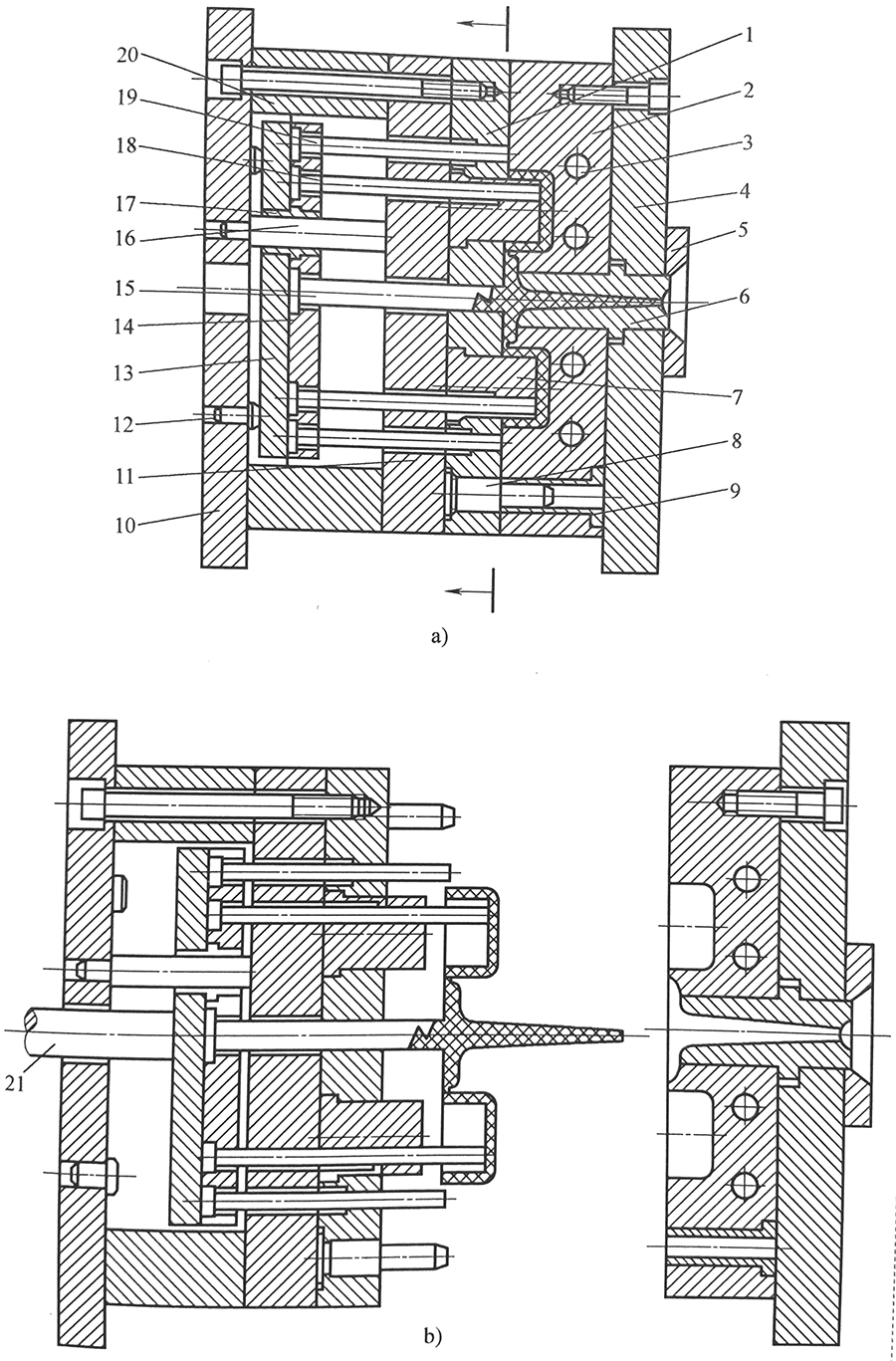

Typical structure of injection moulds

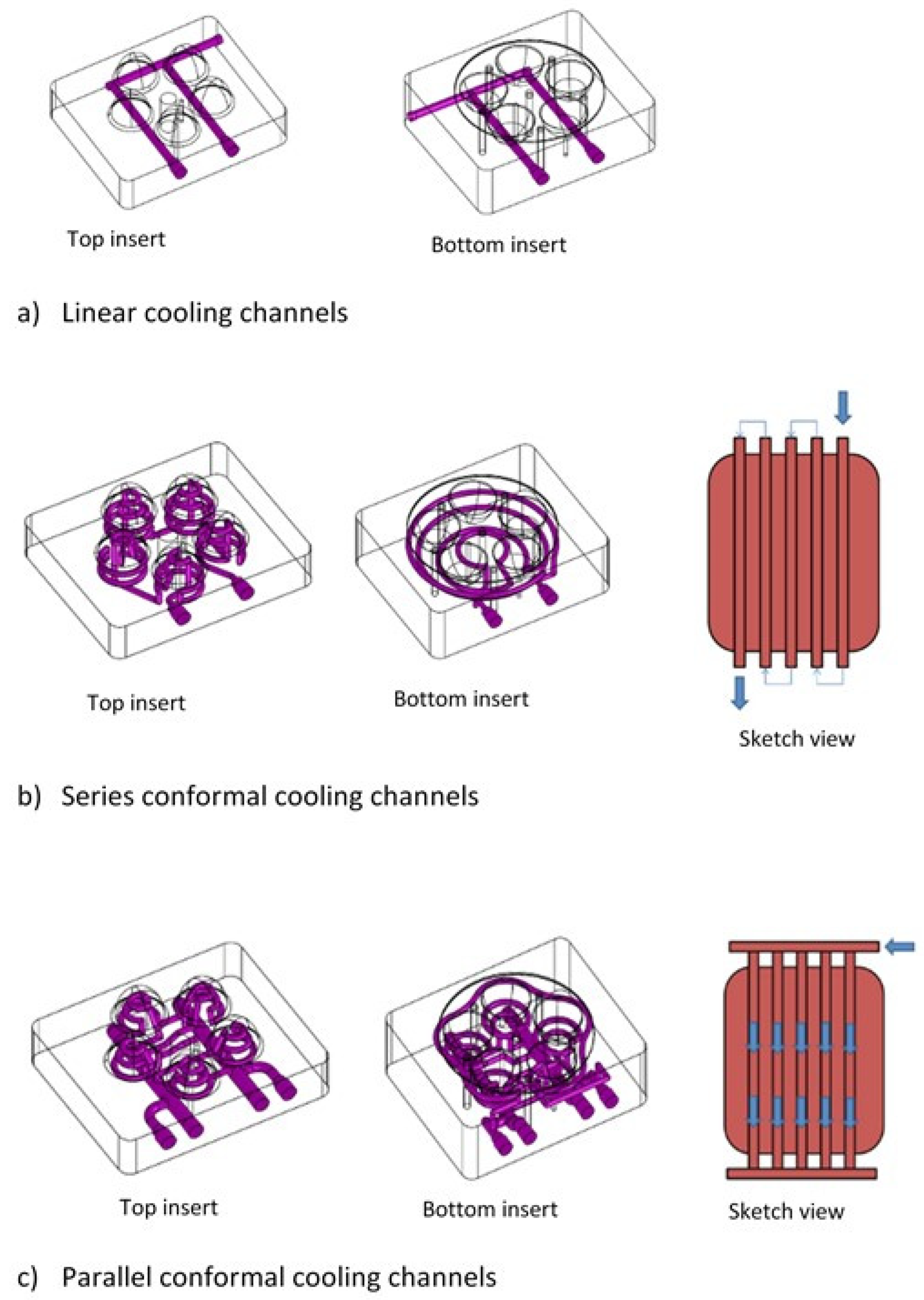

Materials, Free Full-Text

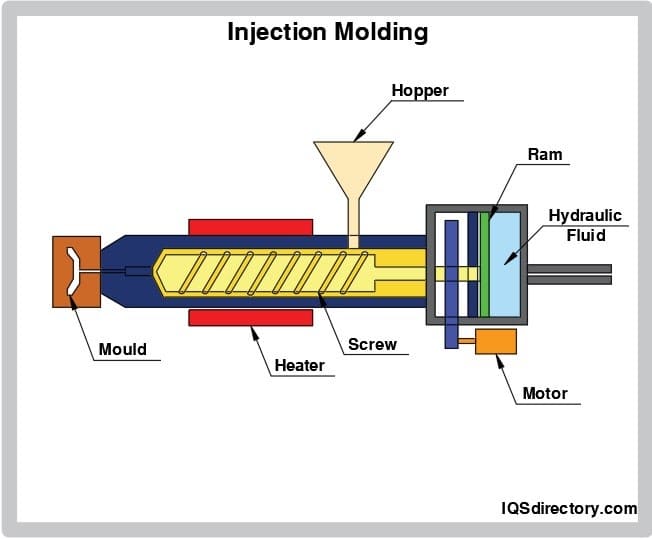

Schematic drawing of the injection molding process.

Plastic Injection Mold Base Functions and Structure - Parts of Mold

Side action removal in a direction different from the main mold opening

Parts of an Injection Mold: Exploring Their Components and Design

The types of Mold base for plastic injection mold

Metal Injection Molding: Advantages, Disadvantages, Process Stages, and Molding Considerations

About injection mold base. What is the function of mold base, by Universe Plastic

Plastic Injection Mold Life, Materials, and Cost for Manufacturers by Neway Precision - Issuu

Plastic Injection Mold Base Functions and Structure - Parts of Mold

Usual mold parts and their function