Introducing lignin as a binder material for the aqueous production

By enabling water-based cathode processing, the energy-intensive N-methyl-2-pyrrolidone (NMP) recovery step can be eliminated, reducing the cost and environmental impact of LIBs. Aqueous processing of high capacity Ni-containing LiNixMn1−x−yCoyO2 (NMC) cathodes is problematic due to lithium-ion(Li+) leaching

Batteries, Free Full-Text

Schematic representation of the different methodologies used to produce

SEM images of (a) Bare PE and (b,c) CCS at different magnification. SEM

IJMS, Free Full-Text

Fermentation, Free Full-Text

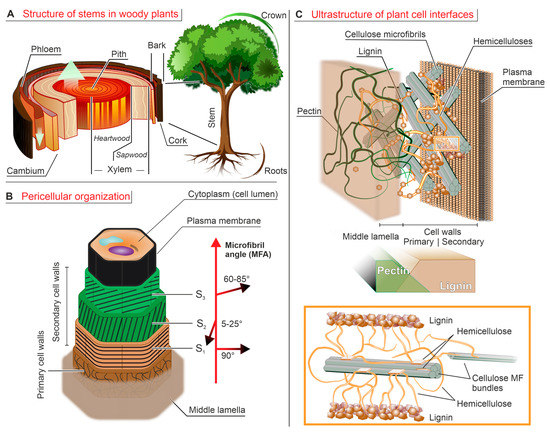

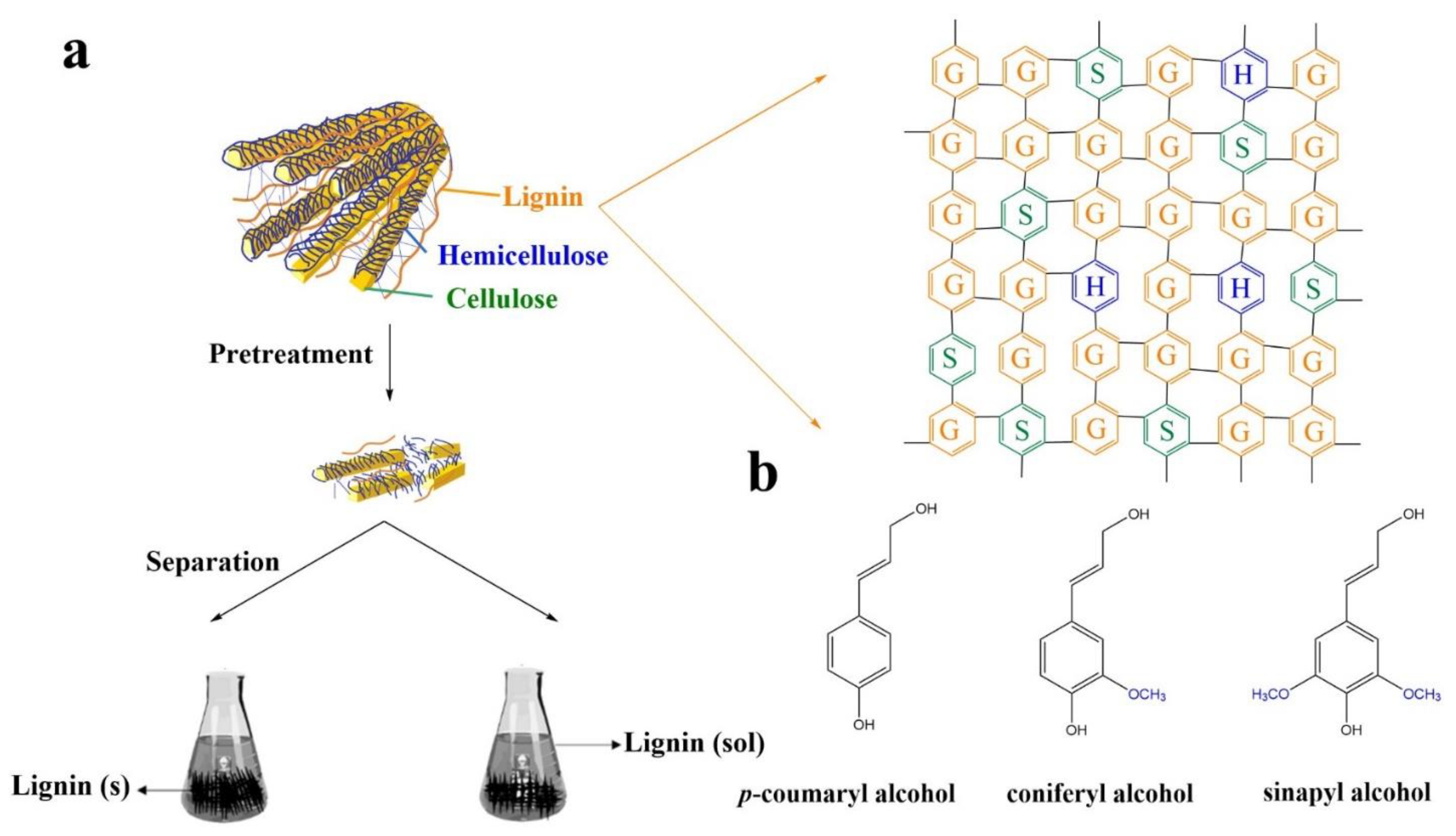

Structure, chemistry and physicochemistry of lignin for material functionalization

When the NMC material is exposed to water Li⁺ starts leaching out from

a)–(f) Area specific impedance (ASI) as a function of voltage for

Historical and prospective lithium-ion battery cost trajectories from a bottom-up production modeling perspective - ScienceDirect

Frontiers Processing, Carbonization, and Characterization of Lignin Based Electrospun Carbon Fibers: A Review

PDF) Introducing Lignin as a Binder Material for the Aqueous Production of NMC Cathodes for Li-ion Batteries.

The role of lignin and lignin-based materials in sustainable construction – A comprehensive review - ScienceDirect

Lignin: A sustainable precursor for nanostructured carbon materials for supercapacitors - ScienceDirect